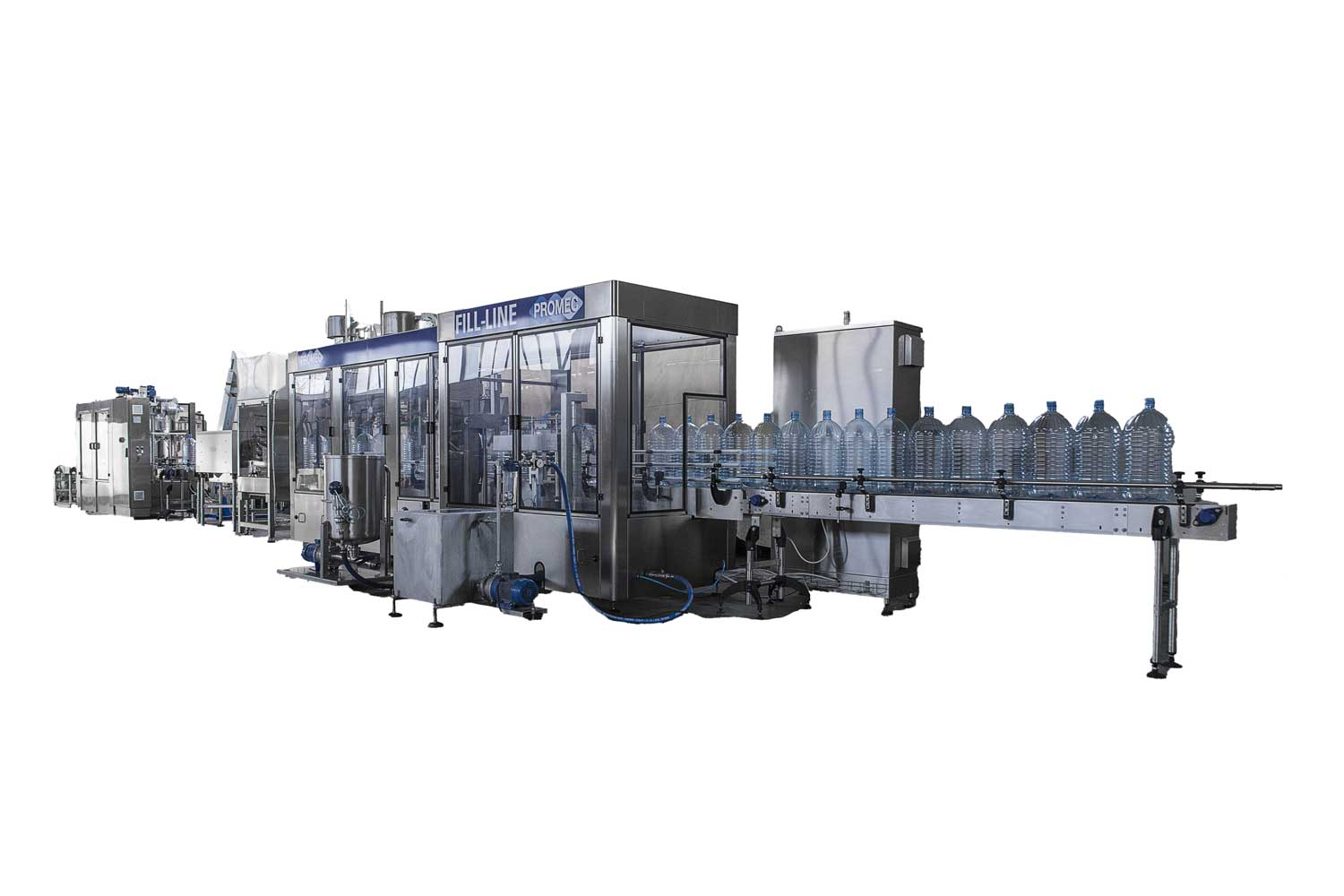

Beverage and liquid product filling lines

SPELS designs, supplies and services filling lines for all kinds of liquid products — from water, juices and beer to oil, dairy drinks and sauces.

We help manufacturers create efficient, hygienic and energy-saving filling systems that are completely ready for operation.

Our solutions cover the entire process cycle: product feeding, filling, closing, labeling, conveying, and final packaging.

We take into account the type of packaging, liquid viscosity, production volumes, and sanitary design requirements.

Types of filling lines

Filling lines for water and beverages — productivity from 500 to 24,000 bottles/hour, PET and glass formats.

- Filling lines for dairy products and oil — aseptic systems with temperature and sterility control.

- Lines for sauces, syrups and thick products — equipped with precise dispensers and heating.

- Universal solutions for breweries and cider producers — complete complexes with capping, bottle rinsing and labelling.

- Compact filling lines for small-scale production — the optimal solution for start-ups and experimental workshops.

We select equipment tailored to the specific product, not simply from a catalog. All lines can be scaled — from manual systems to fully automated solutions.

Our services

SPELS provides full manufacturer support:

- consulting and engineering of bottling lines;

- project development and equipment selection;

- supply, installation and commissioning;

- service, repair and modernisation;

- supply of original spare parts.

We work with leading European manufacturers and guarantee the reliability and precision of every system.

The choice depends on the type of product, volume, viscosity and packaging. We conduct an analysis and offer a technically sound solution for your needs.

Yes, we adapt the equipment to your space and communications, maintaining the continuity of your business.

Our systems work with PET bottles, glass, cans, bags, doy packs and aseptic containers.

Yes. Our engineers perform installation, commissioning, staff training and the first start-up cycle on the product.

Yes. We take care of the entire cycle — from design to commissioning with all the necessary certificates.

We provide scheduled technical service, repairs, spare parts supply and remote monitoring of equipment operation.

We cooperate with leading European brands, supplying original filling lines, pumps, capping and labelling machines.