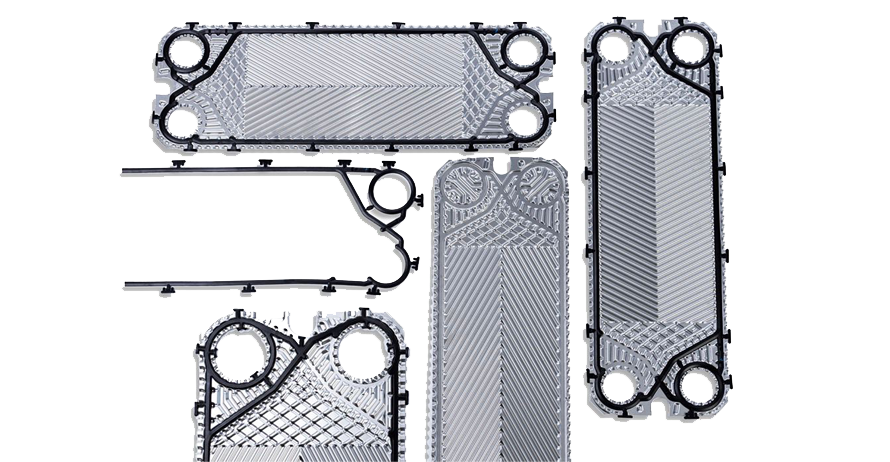

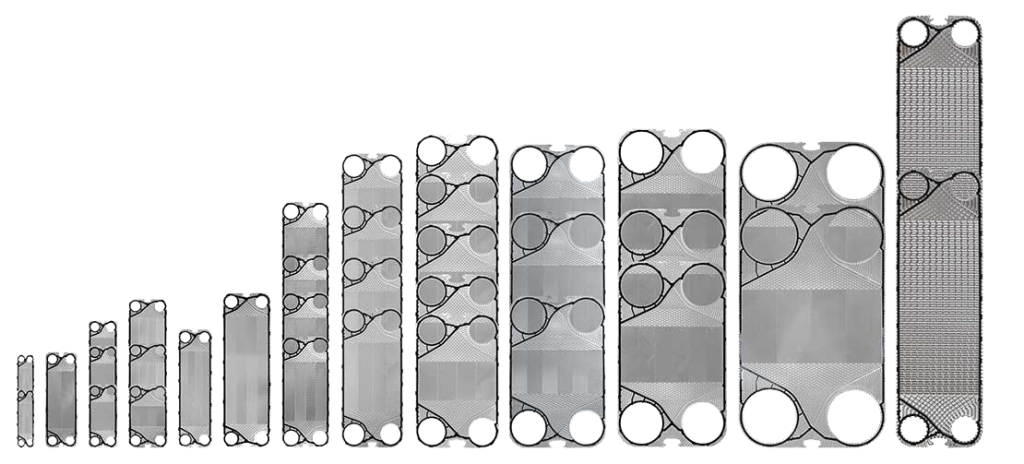

Plates and seals for heat exchangers

SPELS offers its customers high quality plates and seals for heat exchangers from renowned manufacturers. Direct contracts with the manufacturers and the volume of goods sold allow us to maintain the most competitive price.

We supply plates and seals for heat exchangers: ALFA LAVAL, GEA KELVION, SCHMIDT BRETTEN (SIGMA), SONDEX, APV-SPX, CHESTER JENSEN, CIPRIANI, FISCHER, FUNKE, THERMOWAVE, TRANTER (SWEP).

Advantages of working with SPELS:

- in-house production of moulds;

- own unique chemical formulas;

- company certification according to ISO standards;

- development of personalised solutions;

- easy installation process compared to other analogues;

- improved elastomer quality;

- resistance to temperatures;

- 12 months warranty.

A poorly performing heat exchanger reduces safety and process quality and increases energy costs. A malfunction can lead to downtime and significant production losses. Regularly replacing seals and plates avoids these problems and ensures uninterrupted, reliable operation.

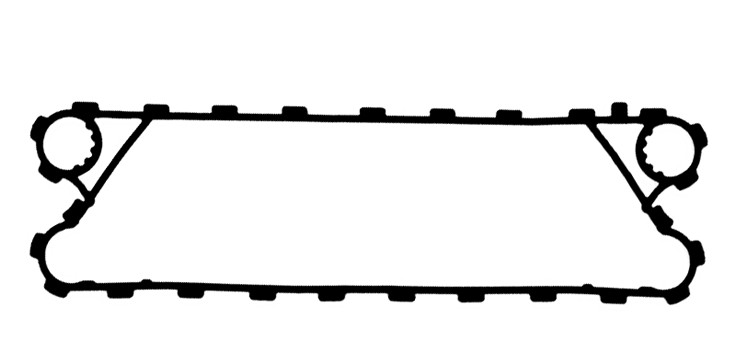

Rubber seals, gaskets and plates are the main components of a plate heat exchanger that prevent the mixing of the working fluids between which heat is exchanged. The choice of seal depends on the type and temperature of the heat transfer medium.

The temperature range depends on the material:

EPDM – ethylene propylene rubber

Nitrile (NBR) – nitrile rubber

EPDM HT – ethylene propylene rubber

VITON I – fluororubber

-15 to +160°C;

-20 to +160°C;

-30 to +175°C;

-10 to 200°C.

Methods of attaching seals and gaskets to the plates:

- glued;

- with a clip-on mounting system.

The plates are made of stainless steel by cold stamping. Typically, the thickness of the plates varies between 0.5 mm and 0.7 mm and depends on the pressure (the higher the pressure, the greater the thickness of the main component). The type of engraving directly affects the heat transfer coefficient.

Materials of the plates:

- Stainless steel (316L);

- Hastelloy C 276;

- Titan Grate 1(G1) and others.

Read more about the heat exchanger here.