Plate heat exchangers for beverage production and the food industry

SPELS supplies and selects plate heat exchangers for all beverage and liquid food production needs.

Our solutions are suitable for companies producing water, juices, beer, dairy products, oil, sauces, syrups, cider, and other liquids, where precise temperature control is critical.

We offer heat recovery, pasteurization, and cooling heat exchangers — from compact units for small workshops to industrial systems for continuous production.

Our engineers help select the heat exchanger type, plate materials, gaskets, and flow configuration according to the product composition, pressure, viscosity, and sanitary requirements.

SPELS provides full cycle of work with heat exchangers:

- selection of equipment for a specific process (heating, cooling, pasteurisation, CIP);

- supply and installation;

- maintenance, cleaning and replacement of seals;

- supply of original spare parts.

We take into account the specifics of each production facility, which is why the heat exchangers we supply operate stably, without energy overconsumption or productivity losses.

Read more about the heat exchanger here.

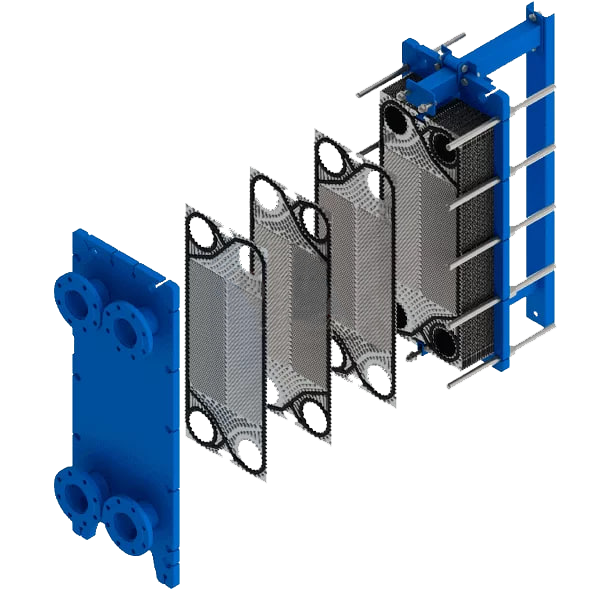

This is a device in which thermal energy is transferred between two fluid streams through thin metal plates. One circuit heats or cools the other without mixing the products.

They are used for cooling, heating, and pasteurization of water, juices, beer, syrups, oils, sauces, and dairy products — wherever precise temperature control is required.

Main types include gasketed, semi-welded, brazed, and block (fully welded)heat exchangers. The selection depends on operating pressure, process media, and sanitary requirements.

The selection depends on the temperature, viscosity, pressure and aggressiveness of the product. We perform engineering calculations and offer the optimal model for your technological process.

Yes, but CIP washersare provided for this purpose, ensuring complete cleaning of the plates between cycles. We can help you select a design that is suitable for multifunctional use.

Technical inspection is recommended every 6–12 months, depending on operating conditions. SPELS provides service and professional cleaning of heat exchangers without damaging the plates.

Yes. We develop custom turnkey solutions tailored to temperature regimes, product type, capacity, and sanitary design requirements.