Pumps for the food and beverage industry

SPELS supplies pumps for all stages of the technological process — from pumping raw materials to bottling the finished product.

We work with companies that produce water, juices, beer, dairy products, sauces, oil, syrups and other liquid media, where flow stability, hygiene and dosing accuracy are important.

Our engineers select pumping equipment taking into account viscosity, pressure, temperature, abrasiveness and chemical composition of the liquidto ensure uninterrupted operation of the line.

SPELS range of pumping equipment

We offer a full range of pumps for the food industry:

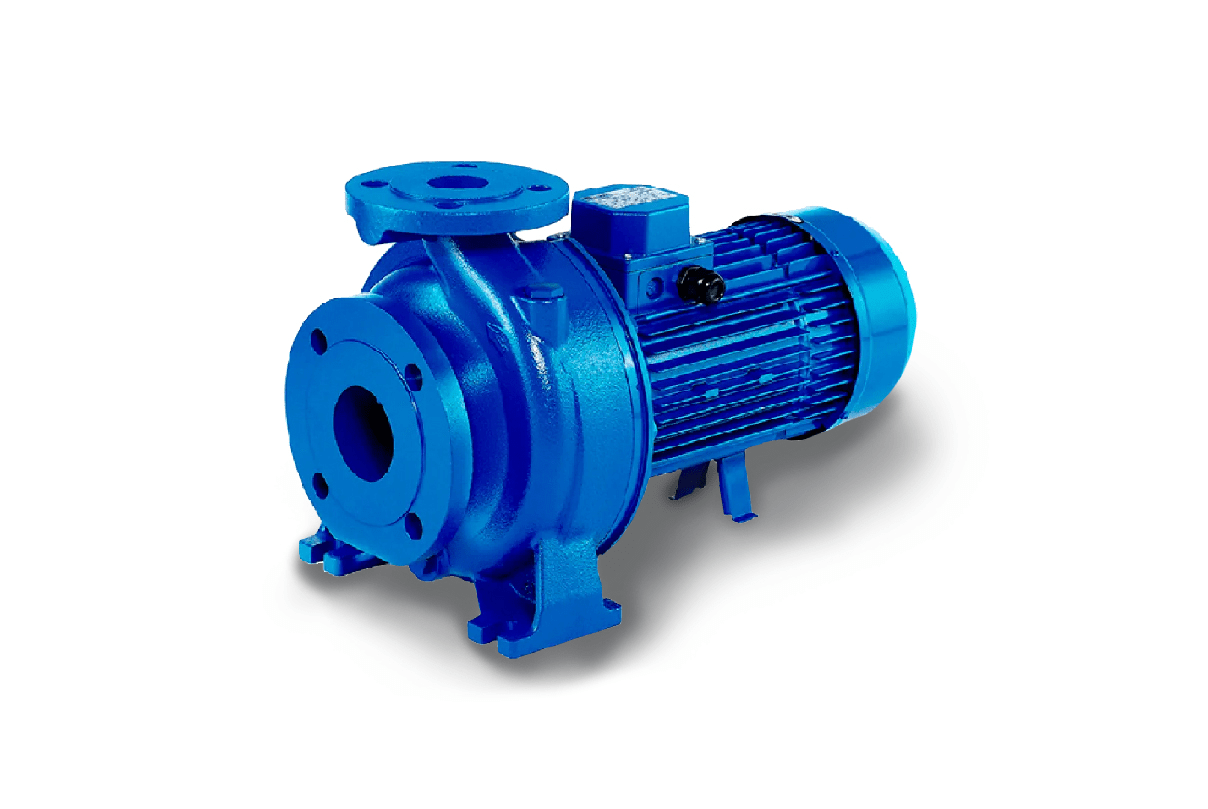

- Centrifugal pumps — for water, juices, beer, wine and other low-viscosity liquids.

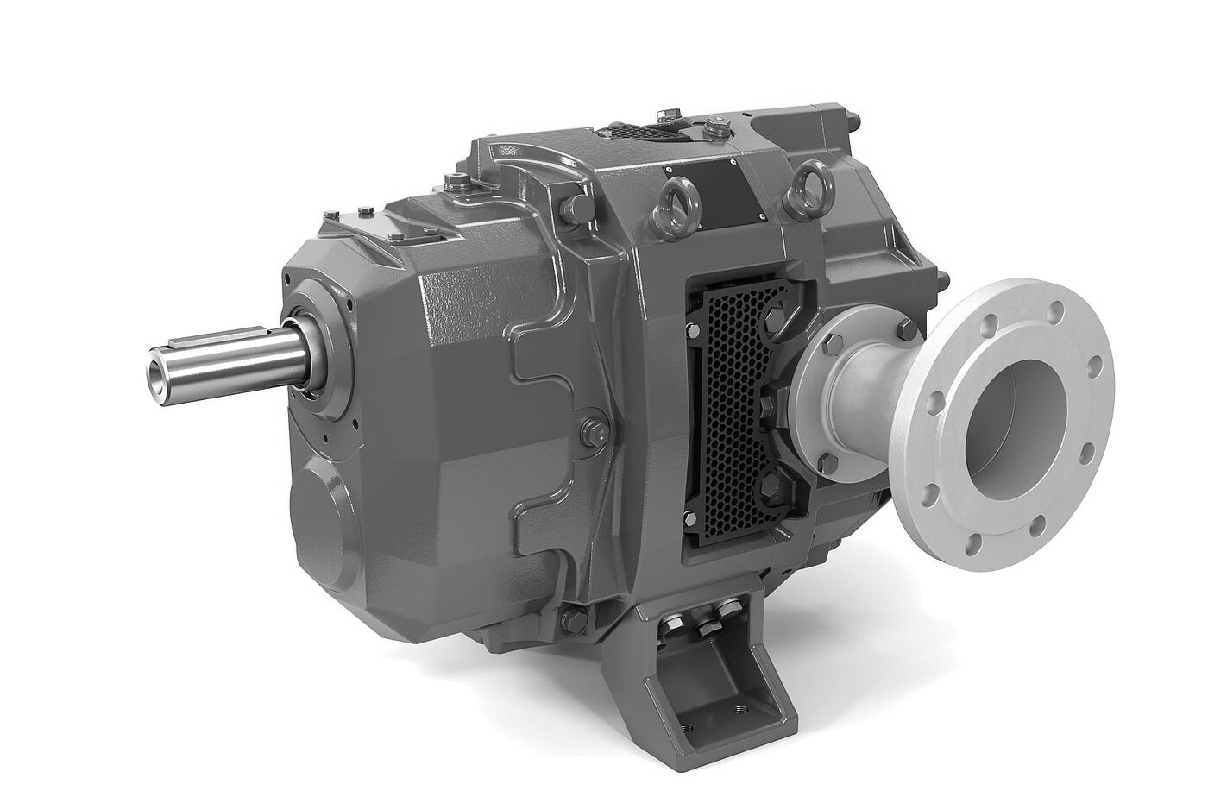

- Rotary vane (cam) pumps — for thick and delicate products such as yoghurts, sauces, molasses, syrups.

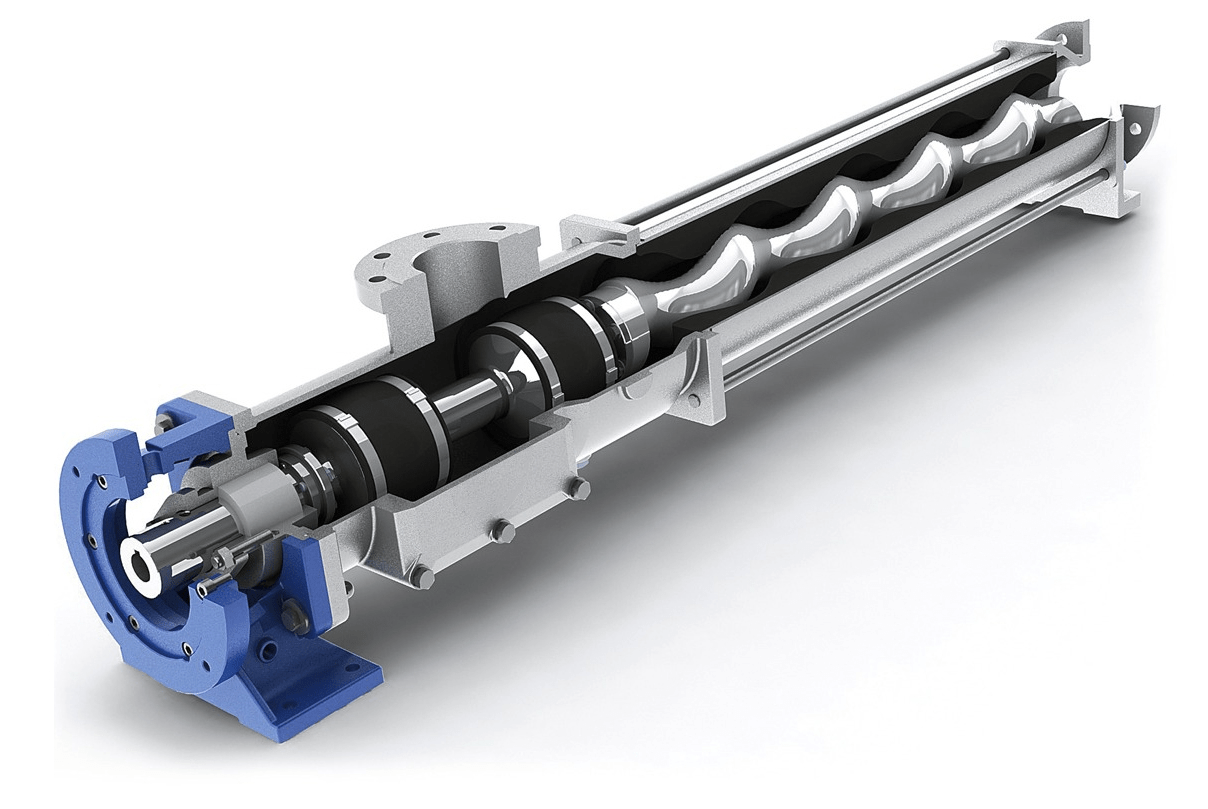

- Screw pumps — for viscous media and products with solid inclusions.

- Self-priming pumps — for CIP washing and pumping products with residual air.

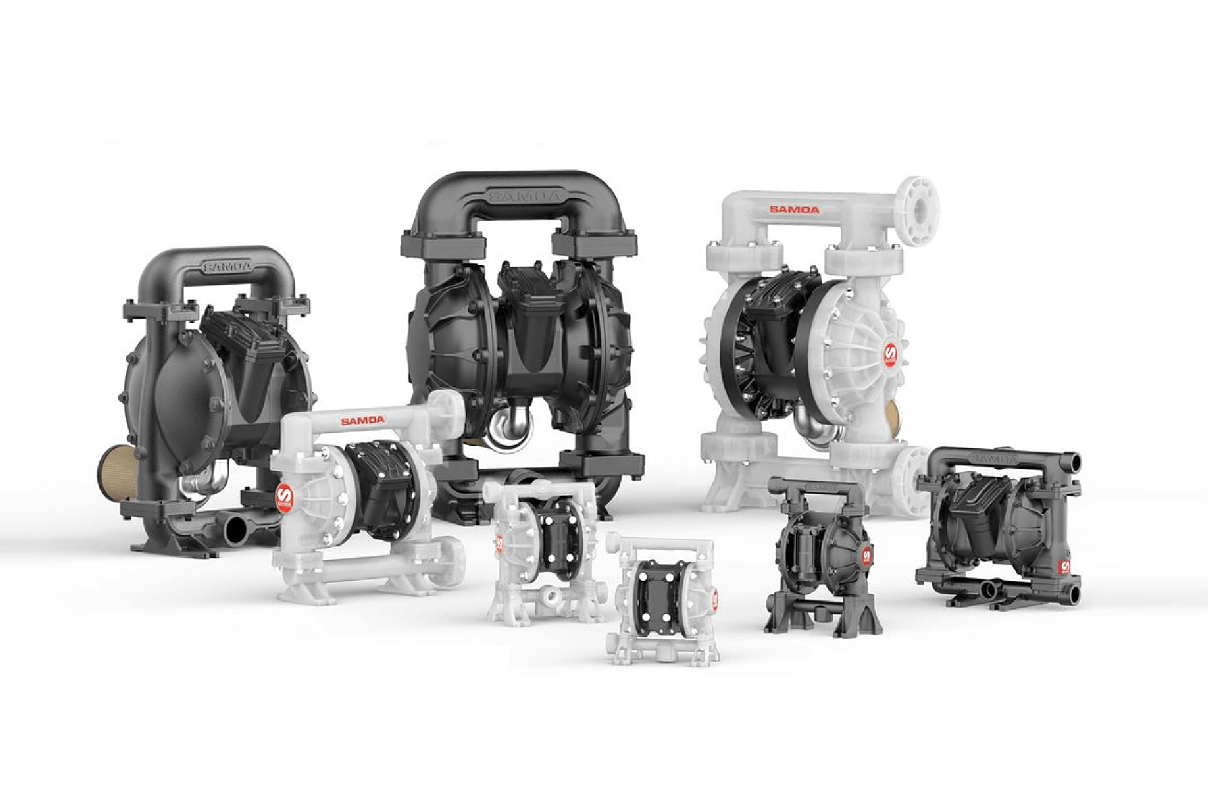

- Dosing pumps — for accurate dispensing of flavourings, additives and concentrates.

- Double jacket pumps — to maintain the temperature of the product during pumping (milk, chocolate, creams).

We work with leading European pump manufacturers and provide original spare parts, service and repairs.

The choice depends on the type of product. For water and juices, a centrifugal pump is used, while for viscous media, a screw, twin screw or cam pump is used. We can help you choose the best option for your process.

Yes. Milk pumps are hygienically designed, have a polished surface, are CIP-cleanable and are EHEDG/3A certified.

We provide a full range of services — from selection and installation to maintenance, repair and supply of spare parts.

Mainly stainless steel AISI 316L or AISI 304, as well as elastomers compatible with food standards (EPDM, FKM, PTFE).I 316L or AISI 304, as well as elastomers compatible with food standards (EPDM, FKM, PTFE).

It is recommended to check the condition of seals and bearings every 6–12 months. SPELS provides on-site service or remote support.

Yes, but only if you have a CIP cleaning system and choose the right seals. We can help you configure your pump system to work with multiple products.

Yes. We conduct audits of pumping stations, and offer replacement or adaptation of pumps to new conditions in order to improve energy efficiency and reliability.