- posted

- article

Screw pumps: how they work and how they are used in industry

Screw pumps: how they work and how they are used in industry Screw pumps are a type of pumping equipment used to pump liquids and gases from one point to another. Screw pumps have many advantages that ensure their efficient operation in various conditions.

One of the advantages of screw pumps is their high performance. They can pump liquids with high solids content and gases with high pressure and high viscosity. This ensures efficient operation in various industries such as oil, chemical, paper and others.

Another advantage of screw pumps is their ability to operate at high temperatures. Many liquids and gases can become viscous or freeze at low temperatures, which can cause the pump to stop. Screw pumps can operate at temperatures of up to 200 degrees Celsius, which ensures stable operation in high temperature environments.

In addition, screw pumps are highly reliable and have a long service life. This is ensured by the fact that they have a minimum number of moving parts, which reduces the risk of wear and tear and breakdowns. In addition, screw pumps are highly precise, which ensures efficient operation and reduces the risk of loss of performance.

This type of pump can be used for a variety of tasks, from pumping water to pumping oil and gas. They are quite versatile and can be used in a variety of environments and industries.

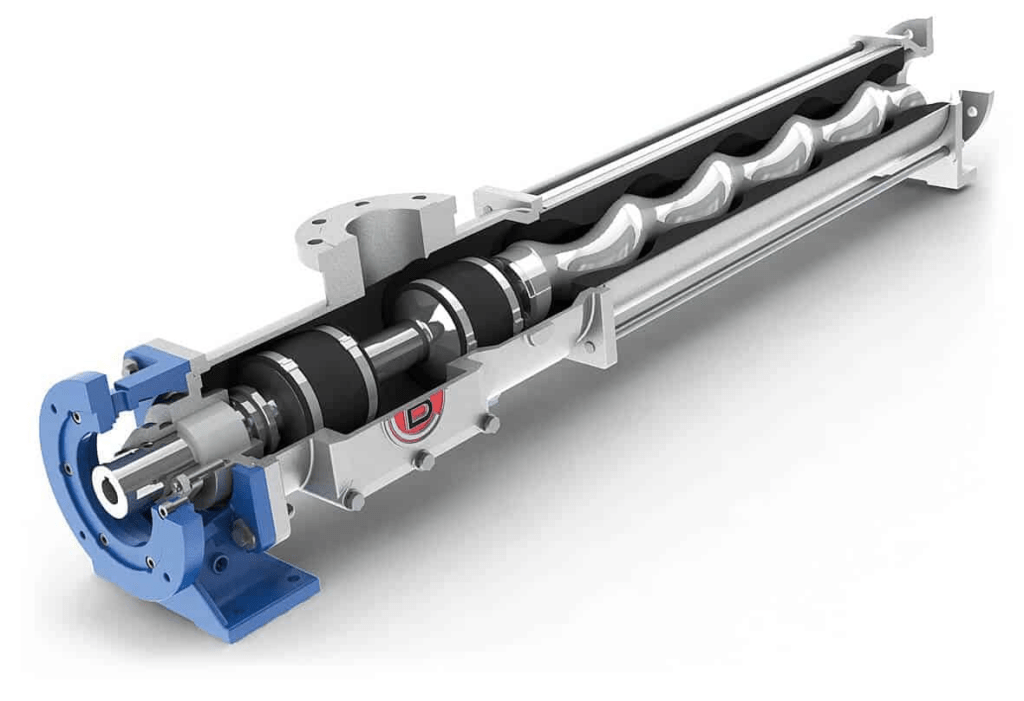

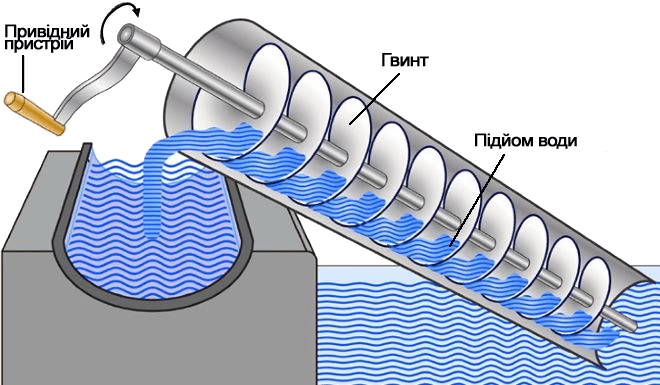

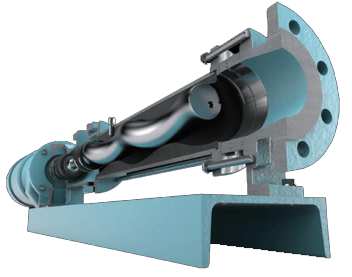

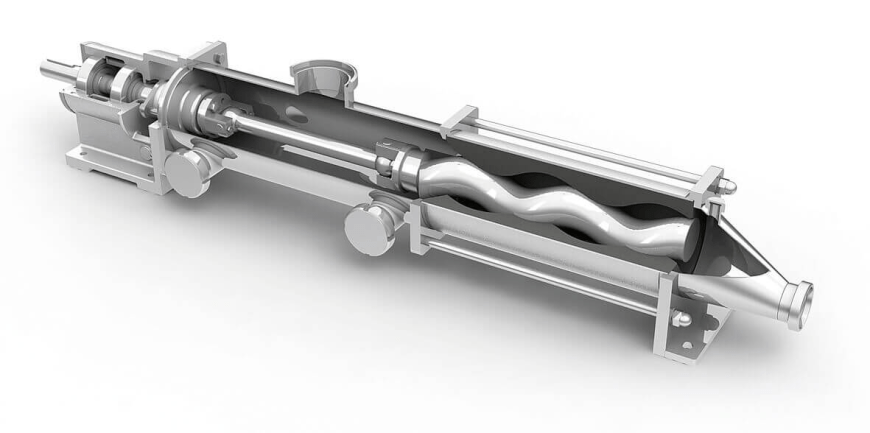

Screw pumps consist of a pair of screw shafts that are shaped like a spiral. These shafts are enclosed in a casing that creates a chamber for the liquid or gas to move through. As the pump operates, the screws rotate against each other, creating a vacuum zone behind the screws. The liquid or gas is then drawn into this zone and is then moved along the chamber to the pump outlet.

There are several types of screw pumps, including single-row, double-row, triple-row and multi-stage pumps. Each has its own characteristics and can be used for different applications.

This type of pump can have different characteristics, such as maximum pumping volume, pressure and fluid viscosity. They can be made of different materials, such as stainless steel, cast iron and aluminium, depending on the application and operating conditions.

In some cases, screw pumps may require a certain level of support and maintenance, as parts can wear out during prolonged operation. Regular cleaning and maintenance can extend the life of the pump.

In summary, screw pumps are an important type of pumping equipment that ensures the efficient movement of liquids and gases in various conditions. They have high performance, can operate at high temperatures and have a long service life if properly maintained. Screw pumps are used in many industries, including chemical, oil, gas, pharmaceutical, food, water and many others.

In the chemical industry, screw pumps are used to transfer liquids with high viscosity and aggressive chemical properties. In the oil and gas industry, they are used to move oil, gas and other products. In the pharmaceutical industry, they are used to transfer liquids that are highly sensitive to contamination.

In the food industry, screw pumps are used to move products such as oil, honey, butter, sauces and more. Water pumps with screw rollers are used to provide water supply in homes, hotels, restaurants and other premises.

In general, screw pumps are indispensable equipment in many industries. They ensure reliable and efficient movement of liquids and gases, which helps to keep processes running smoothly in a variety of production environments.