- posted

- article

Компоненти насосів: роль, призначення та вплив на роботу обладнання

Насоси — це ключові елементи промислових і побутових систем, де необхідне переміщення рідин або газів. Надійність і продуктивність насосної системи напряму залежать від якості її компонентів — від статора та ротора до ущільнень, клапанів і фільтрів. Кожна деталь виконує свою функцію та впливає на загальну ефективність роботи обладнання.

Статор і ротор: серце насосного агрегату

Статор — це нерухома частина насоса, яка формує робочу камеру й відповідає за підтримку стабільного робочого процесу.

Ротор — обертовий елемент, який створює рух рідини або газу. Взаємодія ротора зі статором формує потік, що забезпечує перенесення продукту.

Ці компоненти є критично важливими для будь-якого об’ємного або ротаційного насоса.

Корпус, втулки та конструкційні елементи

Корпус утримує всі частини насоса та забезпечує його механічну стійкість.

Втулки зменшують тертя між деталями, стабілізують обертання та продовжують ресурс роботи агрегату.

Матеріали корпусу та втулок залежать від типу середовища: агресивного, абразивного, харчового або вибухонебезпечного.

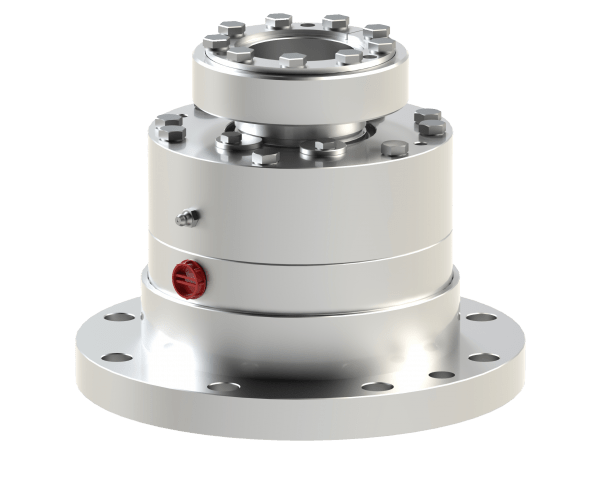

Торцеві ущільнення: захист від витоків

Торцеві ущільнення (mechanical seal) запобігають витокам продукту вздовж вала насоса. Вони утримують рідину в робочому контурі, забезпечуючи герметичність і безпечну роботу обладнання.

Якість торцевого ущільнення — один із ключових факторів надійності насоса.

З’єднувальні та рухомі компоненти

Штоки, муфти, вали та інші з’єднувальні елементи передають рух від приводу до робочої частини насоса.

Від їхньої точності та міцності залежить стабільність роботи агрегату на різних режимах — від мінімального тиску до високих навантажень.

Клапани, сідла та шарики: керування потоком

Клапанна група контролює напрям руху середовища, відкриваючи або закриваючи проходи всередині насоса.

Сідла клапанів і шарики забезпечують точне прилягання, стабільний тиск і відсутність зворотного потоку.

У мембранних і гідравлічних насосах клапанна система — ключ до правильного дозування.

Мембрани та діафрагми

Мембрана — еластичний елемент, який створює тиск і забезпечує переміщення рідини в діафрагмових насосах.

Вона повинна бути хімічно стійкою, еластичною та зносостійкою, адже працює під циклічними навантаженнями.

Прокладки та O-ring: дрібні деталі, що визначають надійність

Прокладки та кільцеві ущільнення забезпечують повну герметичність корпусу й з’єднань.

Їхній стан безпосередньо впливає на роботу насоса — навіть невелика течія може вивести обладнання з ладу.

Фільтри: захист насосної системи

Фільтри очищують середовище від механічних домішок та запобігають зносу внутрішніх компонентів.

Регулярна заміна фільтрів — один з основних етапів технічного обслуговування.

Ремкомплекти: швидке відновлення працездатності

Ремкомплекти включають набір оригінальних деталей для планового ремонту: мембрани, клапани, прокладки, втулки, ущільнення тощо.

Своєчасна заміна цих елементів гарантує:

- стабільні параметри насоса,

- мінімальні простої,

- продовження терміну служби обладнання.