- posted

- article

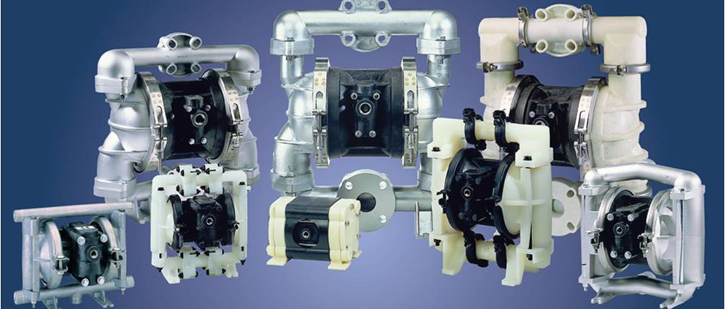

Maintaining the diaphragm pump: important spare parts and their replacement

A diaphragm pump is a device used to move fluid from one place to another using a membrane. It is often used in industry, medicine and other fields.

The main components of a diaphragm pump are diaphragms, valves and pump heads. The diaphragms are usually made of elastomers such as nitrile, EPDM or fluorocarbon rubber and are very important for the correct operation of the pump. Valves are usually made of stainless steel or plastic and they regulate the flow of fluid from the diaphragm to the pump head. Pump heads are usually made of brass or other durable materials and they provide the pressure needed to move the fluid through the pump.

If you have a diaphragm pump and you are looking for spare parts for it, you first need to know the model of your pump. There are many different types of diaphragm pumps, and the spare parts may be different for each type.

Once you know the model of your pump, you can find the appropriate spare parts in specialist shops. Typically, spare parts for diaphragm pumps can be purchased individually or as a replacement kit, which contains all the necessary parts for replacement.

The most commonly replaced parts for diaphragm pumps are diaphragms and valves. Diaphragms can be subject to wear or rupture after prolonged use, so they should be replaced periodically to avoid fluid leakage and other pump performance problems. Valves can also become worn and damaged, which can lead to malfunctions in the pump.

In addition to diaphragms and valves, other parts that can be replaced on a diaphragm pump include pump heads, fittings, hoses and other parts. If you need to replace parts on your diaphragm pump, you should contact your spare parts supplier or the manufacturer of your pump for more information and advice on selecting the correct parts.

The need to replace spare parts on a diaphragm pump can be caused by a variety of factors, such as prolonged use, misuse of the pump, or simply normal wear and tear. Replacing spare parts can save you money and time in repairing and keeping your diaphragm pump in good working order.

In addition to replacing parts, some diaphragm pump problems can be solved by adjusting pump parameters such as pressure, flow, speed, and others. For example, if you notice a decrease in fluid flow from your pump, you may need to clean or replace the filters, which may be dirty. If you find fluid leaking from your pump, you may need to replace valves or check that all pump components are properly assembled and secured.

The best way to avoid problems with a diaphragm pump is to perform regular maintenance and preventive inspection. This can include cleaning filters, replacing diaphragms and valves, and checking pump heads and other pump components. Regular maintenance can help prevent fluid leakage, reduced flow and other pump performance issues, keeping your pump running efficiently and smoothly.