- posted

- article

Rotary pumps. Advantages and disadvantages

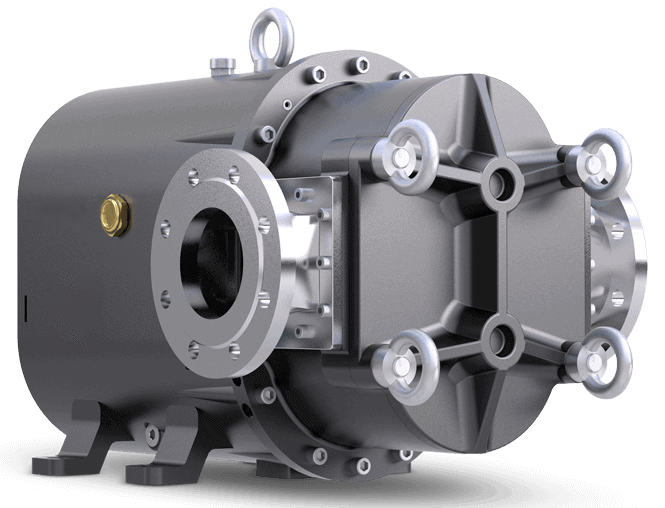

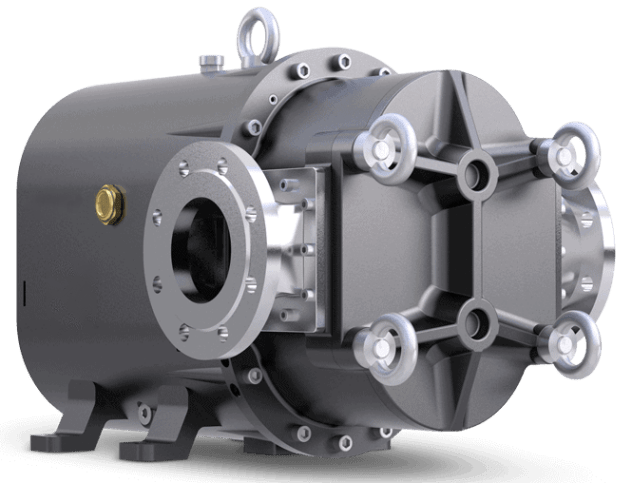

A rotary pump is a mechanism for pumping liquid or gas used in a variety of industries, including industry, transport, construction and agriculture.

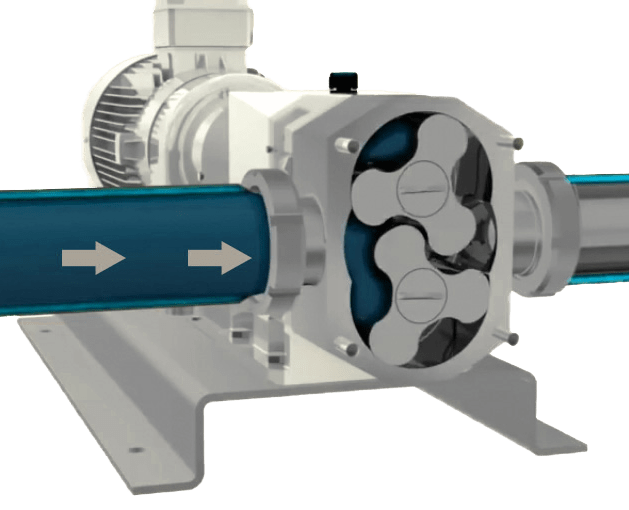

The basic design of a rotary pump is that it consists of two rotors moving at a small distance from each other. One rotor has projections that fit into sections of the second rotor, forming a seal between them. As the rotors move, the liquid or gas seeps through the seal and is pumped into the system.

There are several types of rotary pumps, such as gear pumps, vane pumps, suction pumps and others, each with its own characteristics and applications.

A gear pump consists of two toothed rotors that move in opposite directions. A vane pump has blades on one rotor that pump liquid or gas from one side to the other. A positive displacement pump is used for pumping gases and is constructed of two rotors that move in the direction of each other.

Rotary pumps have many advantages over other pump types, such as high performance, reliability and efficiency, and the ability to operate at high temperatures and high pressures.

In addition to their advantages, rotary pumps also have some disadvantages that need to be considered. For example, they can be noisy and generate vibrations that can affect the environment or cause damage to equipment. They can also be vulnerable to contamination and other defects that can affect their performance and service life.

However, when used and maintained properly, rotary pumps can be very efficient and reliable. They are widely used in many industries, including oil and gas, chemical and food processing, transport and construction.

One of the key advantages of rotary pumps is their ability to handle viscous liquids and thick materials, making them ideal for heavy-duty applications such as oil and gas and chemicals.

Another important advantage of rotary pumps is their high efficiency, which reduces energy consumption and lowers the cost of operating the equipment. This is especially important in environments where electricity is expensive or limited.

In addition, rotary pumps are lightweight and compact, making them easy to move from one location to another and fit into a small footprint.

In general, rotary pumps are indispensable in a large number of applications, providing efficient, fast and reliable transport of liquids and materials.

When selecting a rotary pump, factors such as the type of material to be conveyed, capacity and performance, the need for interaction with other equipment and the appropriate operating conditions must be considered.

Overall, rotary pumps are essential elements in modern industry and transport, providing a wide range of applications in many sectors. They enable efficient, fast and reliable transport of liquids and materials, reducing costs and increasing productivity.

Although rotary pumps have some disadvantages, their advantages allow them to be used in a large number of applications. When used and maintained properly, they can be a reliable and efficient solution for transporting liquids and other materials in a variety of industries.