- posted

- article

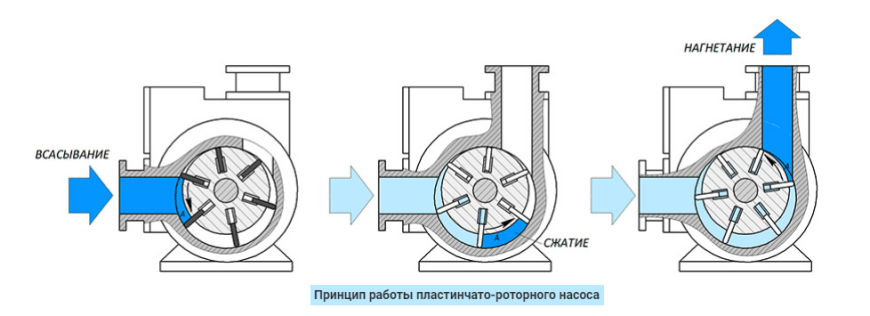

Rotary pump: structure and function

The rotary pump is an efficient and reliable solution for pumping liquids, especially in industry and manufacturing. But as with any machine, rotary pump spare parts can wear out over time and need to be replaced. In this article, we will take a look at the main rotary pump spare parts and their functions.

The rotor is the main part of a rotary pump that pumps liquid. The rotor consists of numerous vanes that rotate in the crystal space, creating a vacuum and pressure that pumps the liquid through the pump. The rotor can be made of different materials such as steel, stainless steel or titanium.

Rotary pump casing is an important part that holds the rotor and ensures the tightness. The casing can be made of different materials such as cast iron, steel or stainless steel. Depending on the type of rotary pump, the casing can have one or more chambers for pumping fluid.

The sealing mechanism consists of two O-rings that ensure a tight seal between the rotor and the pump casing. The O-rings can be made of different materials such as ceramic, carbon or Teflon.

The lagers provide support for the rotor and keep it in the correct position. The lagging can be made of different materials such as steel or ceramic and of different types such as ball, roller or rod. The choice of material and type of lager depends on the operating conditions of the pump, such as temperature, load and rotational speed.

The shaft seal provides a tight seal between the shaft and the pump casing. It can be made of different materials, such as ceramic, carbon or Teflon, and have different types, such as mechanical seals or lip seals.

The rotary pump drive is the mechanism that enables the rotor to rotate. It can be made of different materials and have different types, such as an electric drive or a hydraulic drive.

The rotary pump valve ensures the correct direction of fluid flow and prevents it from returning. It can be made of different materials and have different types, such as a ball valve or a disc valve.

Each rotary pump spare part has its own important role to play in the proper functioning of the pump, so it is important to follow the manufacturer's recommendations for maintenance and spare parts replacement. Regular inspection and maintenance can significantly extend the service life of the rotary pump and reduce the risk of accidents. In addition to these spare parts, a rotary pump may also include other important components such as filters, pressure gauges, pressure regulators, and others.

The filter in a rotary pump ensures that the liquid is cleaned before it enters the system. It can be made of different materials and have different types, such as a mechanical filter or a cartridge filter.

The pressure gauge in a rotary pump measures the pressure of the pumped liquid and allows you to control the operation of the pump. It can be made of different materials and have different types, such as an indicator pressure gauge or a digital pressure gauge.

The pressure regulator in a rotary pump allows you to control the pressure of the pumped fluid and ensures the correct operation of the system. It can be made of different materials and have different types, such as a spring pressure regulator or an electronic pressure regulator.

Given the importance of each spare part to the operation of a rotary pump, regular inspection and maintenance is an important step in maintaining efficient and safe pump operation. Recommendations for maintenance and replacement of spare parts should be made by the pump manufacturer, and it should be remembered that each pump type may have its own specific maintenance requirements.