- posted

- article

Spare parts for the plate heat exchanger

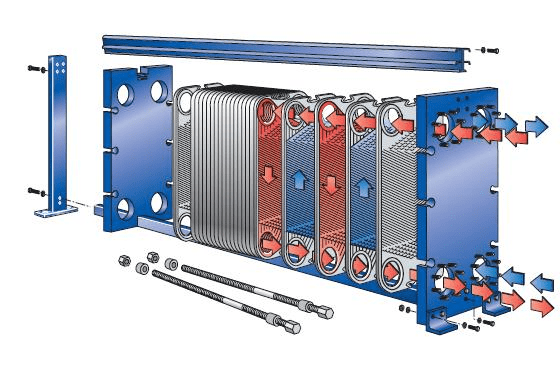

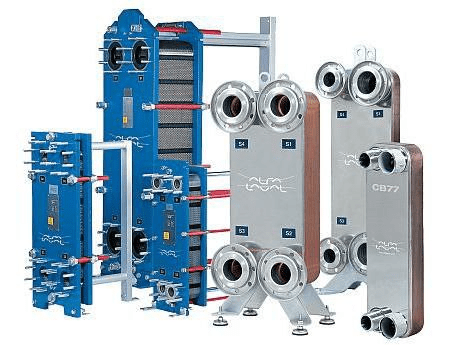

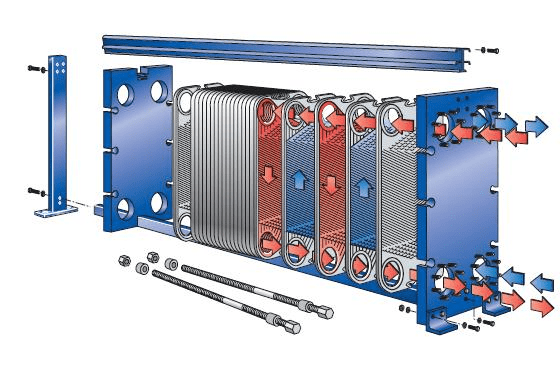

Heat exchangers are devices designed to transport heat between two media. They are used in a variety of industries, such as industry, energy, transport, etc. In order for a heat exchanger to perform its functions, it needs spare parts to ensure its proper operation and increase its service life.

One of the key components of a heat exchanger is the tubes. They transport the heat transfer fluid and must be made of a material that is resistant to high temperatures and corrosion. Alloys such as stainless steel, copper and aluminium are often used for this purpose. In addition, different types of tubes can be used to increase the efficiency of the heat exchanger, such as spiral, laminar, corrugated, etc.

Another important component of the heat exchanger is the flange. It is used to connect the various elements of the heat exchanger and must ensure that the connection is leak-proof. Flanges can be made of different materials, such as steel, brass, aluminium, etc., and have different types of connection, such as welded, screwed or flanged.

Heat exchangers also use gaskets to ensure that the connection between the heat exchanger elements is tight. They can be made of different materials, such as graphite, asbestos, ceramics, etc., and have different shapes and sizes depending on the design of the heat exchanger. One of the main enemies of heat exchangers is corrosion, which can lead to element failure and reduced efficiency of the heat exchanger. Various methods are used to combat corrosion, such as protective coatings, cathodic protection, the use of anti-corrosion materials, etc.

In addition, one of the main components of heat exchangers is the heat transfer fluid. The choice of heat transfer fluid also plays an important role in the heat exchange process. The main selection criteria are temperature, viscosity, corrosion properties and cost. There are several types of heat transfer fluids, the most commonly used being water, steam, oils and ethylene glycol solutions. The choice of heat transfer fluid depends on the requirements for the heat exchange process and the operating conditions of the heat exchanger.

It is worth noting that spare parts for heat exchangers are a key element in ensuring the reliable operation of heat exchange equipment. Therefore, when choosing spare parts, it is necessary to contact trusted manufacturers who have the appropriate certificates and licences. It is also necessary to take into account the requirements for spare parts, their compliance with quality and safety standards.

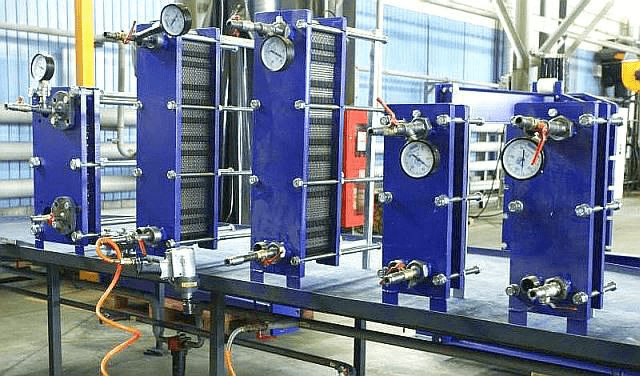

In addition, regular maintenance and preventive maintenance is essential for the efficient operation of heat exchangers. This will allow timely detection and elimination of possible breakdowns and prevent unforeseen equipment failures. It should be borne in mind that maintenance and repair of heat exchangers should be carried out by qualified specialists using special tools and equipment.

Thus, spare parts for heat exchangers are one of the most important elements in ensuring reliable and efficient operation of heat exchange equipment. When choosing them, many factors must be taken into account, such as the type of heat transfer medium, temperature conditions, quality and safety standards. At the same time, it is important to use trusted manufacturers and carry out regular maintenance to maintain optimum equipment performance.